Just 100 kilometers south of Paris, the Loiret district, in the Loire Valley, is a completely different world: Instead of lights and tourists, there are forests and farmland. One of the largest towns, Montargis, is notable mostly for its bridges and for a statue commemorating the medieval legend of a brave dog that avenged its knight-master’s death.

The average age of people in the Montargis region is among the highest in the entire country — but it also has the lowest ratio of doctors to patients. The Centre Hospitalier de l’Agglomération Montargoise (CHAM), on the outskirts of town, with a staff of 2,000, serves a population of about 180,000 people spread out over 3,000 square kilometers (1,150 square miles). It sees 65,000 emergency patients every year.

And in the entire hospital, there is just one CT scanner.

This has not been an optimal state of affairs. The bottleneck, as one might imagine, keeps patients waiting and makes visits to the emergency room (ER) last even longer. The administrators of the hospital knew something needed to be done.

“It was essential for CHAM to acquire a scanner exclusively dedicated to [the ER] in order to optimally meet the growing demand and handle emergency situations,” says Jean-Luc Davigo, CHAM’s director.

Answering the (local) call

Until recently, if CHAM wanted to order a new scanner, it had to import one from abroad. This was not aligned with CHAM’s strategy of reducing its carbon footprint.

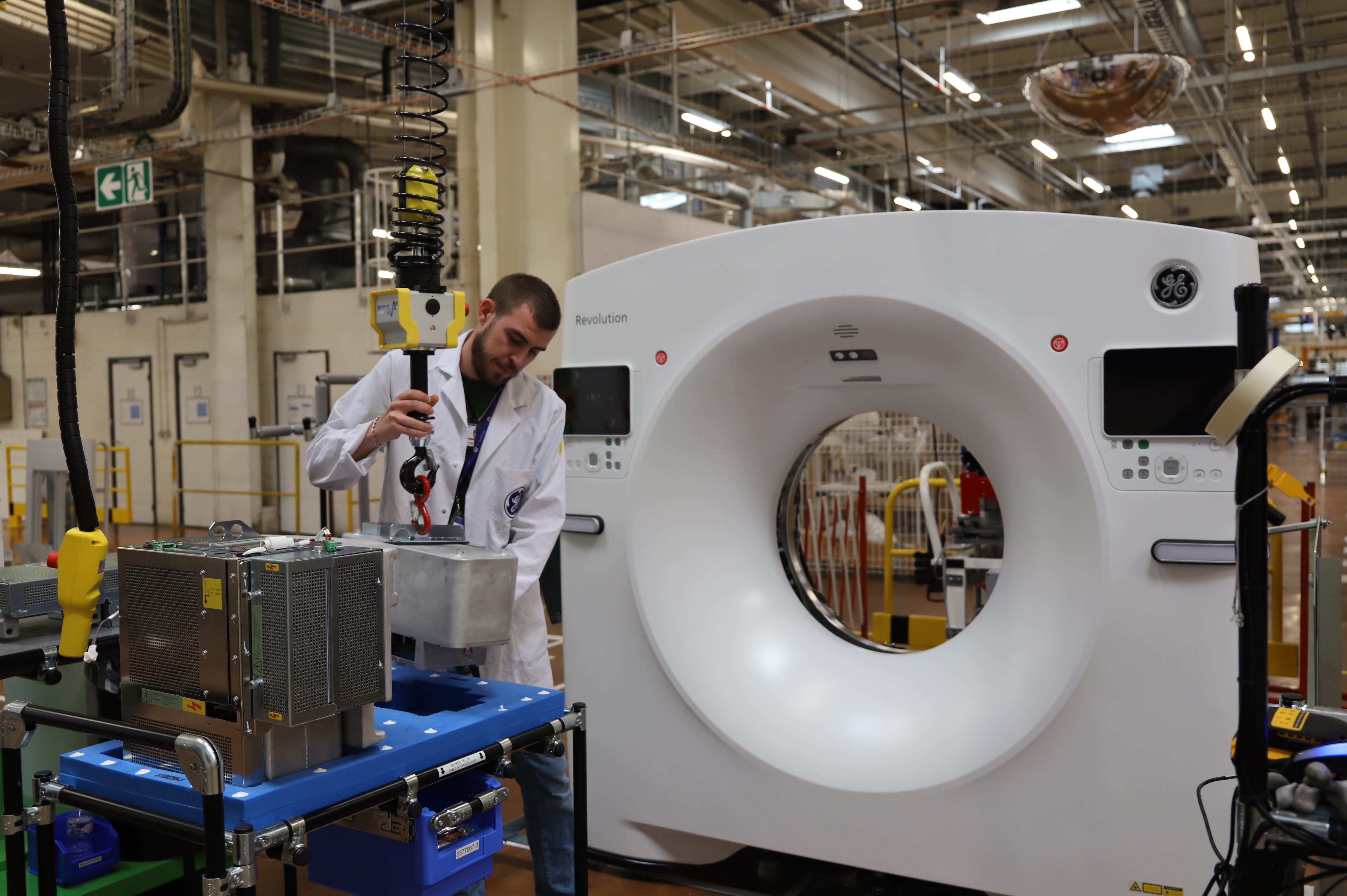

But GE HealthCare just began assembling its Revolution™ Maxima CT scanner in its center of excellence in Buc, outside Paris. CHAM is slated to receive the first scanner off the line.

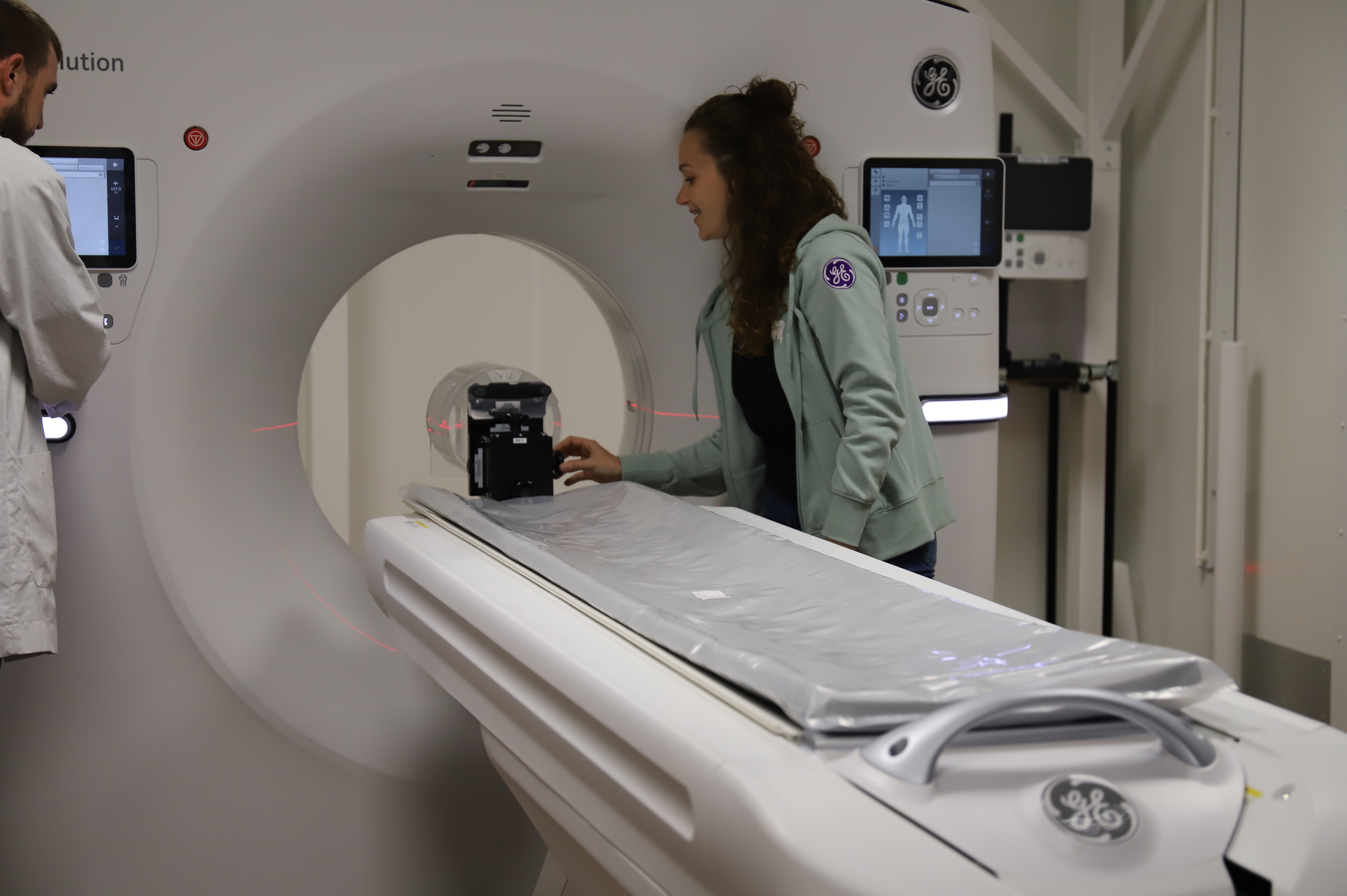

The Revolution Maxima CT scanner is a performance scanner and a versatile machine. It can do a variety of exams, from cardiology to oncology to a routine physical exam to detect and prevent serious illnesses. It has an automatic positioning system, powered by AI, that reduces patient exposure to radiation. And it’s quick — it can scan a full-grown adult in 10 seconds — which makes it ideal for an overburdened emergency department that sees all sorts of patients.

“This new equipment is designed for quick and efficient use, allowing for immediate diagnostics,” says Davigo. In other words, it’s an excellent device for a hospital like CHAM, located in the middle of a rural area.

The existing scanner, meanwhile, will continue to serve the medical imaging department. Without competition from the ER, doctors will be able to schedule more outpatient consultations. Davigo expects the waiting time for a scan to be reduced to no more than 48 hours.

A sustainable move

Previously, the Revolution Maxima was manufactured in GE HealthCare’s Beijing plant. Transporting a scanner to France took several weeks by sea or by air, plus extra time to clear customs. It was also costly in terms of carbon emissions. Moving manufacturing to Buc will reduce lead time for European customers and make the scanner more eco-friendly.

“This is very good news in Buc,” says Riadh Tounsi, director of CT for GE HealthCare International. “This is something new. Usually, we import equipment that was manufactured in the U.S., China or Japan. This is the first time we decided to bring a CT product to a manufacturing line in France. This will have a big impact on customers.”

France is ideally positioned for distribution throughout Western Europe, which, Tounsi says, made Buc a more compelling location than some of GE HealthCare’s other European plants. The new production site is expected to reduce the carbon emissions for transporting the new scanners by 84% as compared with 2022. Eventually, the distribution area will expand to North Africa and the Middle East.

Pride in production

Expansion of the Buc line was projected to take one year and cost 1 million euros; the project came in on time and under budget. While key components of the scanner will still be manufactured in Beijing and in Bengaluru, India, final assembly will take place in Buc, a great source of pride for both GE HealthCare workers in Buc and its French customers.

“It’s a strong added value,” Tounsi confirms. “Customers in France are sensitive to the ‘made in France’ branding. It’s a real program on the government level.” Products labeled “made in France” are expected to meet certain quality standards, and keeping manufacturing local could impact employment rates in the region.

Initially, the Buc plant will manufacture two to three of the scanners per week, but Tounsi says that as the team grows more experienced, it should be able to increase production.

For Davigo, the director of CHAM, the Revolution Maxima is part of the future of healthcare. “The installation of this dedicated scanner is part of a broader approach to continuously improve our healthcare services,” he says. “The emergency department is often the first point of contact for patients with the hospital, and having the best diagnostic tools is crucial for ensuring fast and accurate care.”